Plating Rectifiers Parallel Pairing

Sol Rectifiers PHFSPD

Programmable High Frequency Switching Power Devices

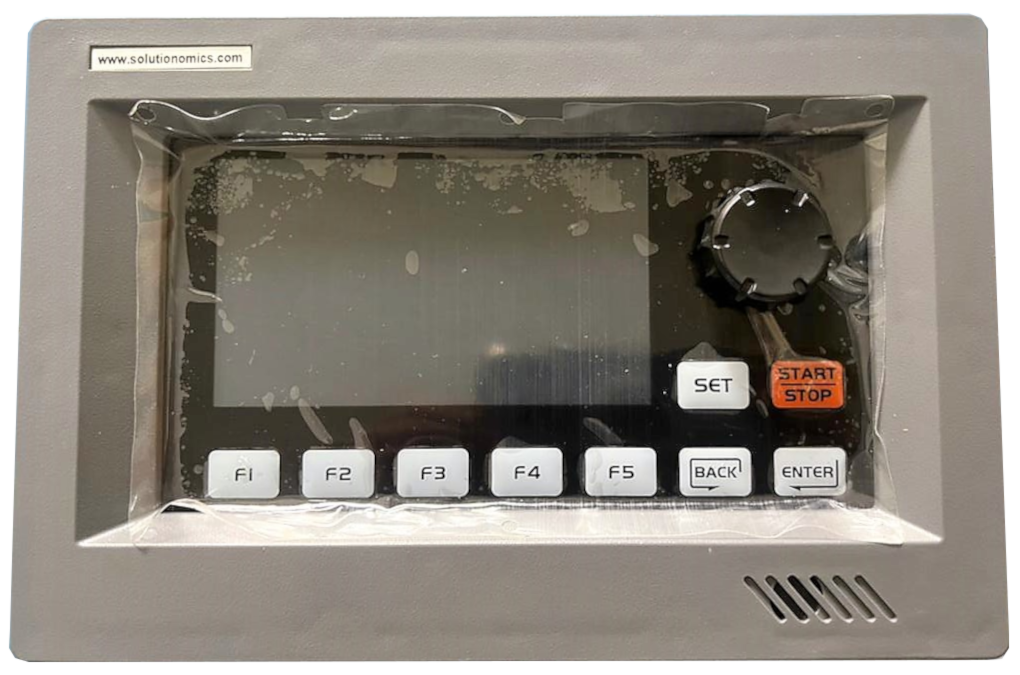

Parallel Pairing Remote Control Plating Rectifiers

Parallel Pairing

Designed to offer capex flexibility for plating plants conceptualization and future expansions.

Parallel pairing provides more adaptability options in plating plants set ups, assets management for the present and for future expansions.

Up to 4 units of the same output rating can be paired.

For instance, two units each rated 12 V 5000 A output and paired will provide 12 V 10000 A output. Regulation of the paired rectifier units is made from a single remote controller.

Improved Ripple with Parallel Pairing

Ripple ratings based on unit A output capacity:

30 A to 1000 A: < 2 %

1500 A to 3000 A: < 3 %

4000 A to 5000 A: < 4 %

6000 A to 10000 A: < 5 %

It is technically possible to improve ripple using our Parallel Pairing units. For example, a single unit 12 V 10000 A will get < 5 % ripple but if you parallel pair two 12 V 5000 A you will still get 12 V 10000 A but at < 4 % ripple.