Electrocoagulation Rectifiers

Sol Rectifiers PHFSPD EC

Programmable High Frequency Switching Power Devices

Description

Our electrocoagulation rectifiers are reasonably priced, provided with automated polarity reversing as a standard feature suitable for the most demanding wastewater treatments applicable found in many industries:

Residential

Hospitality

Electroplating

Mining and metal processing

Municipal sewage

Petroleum

Pulp and paper

Textile

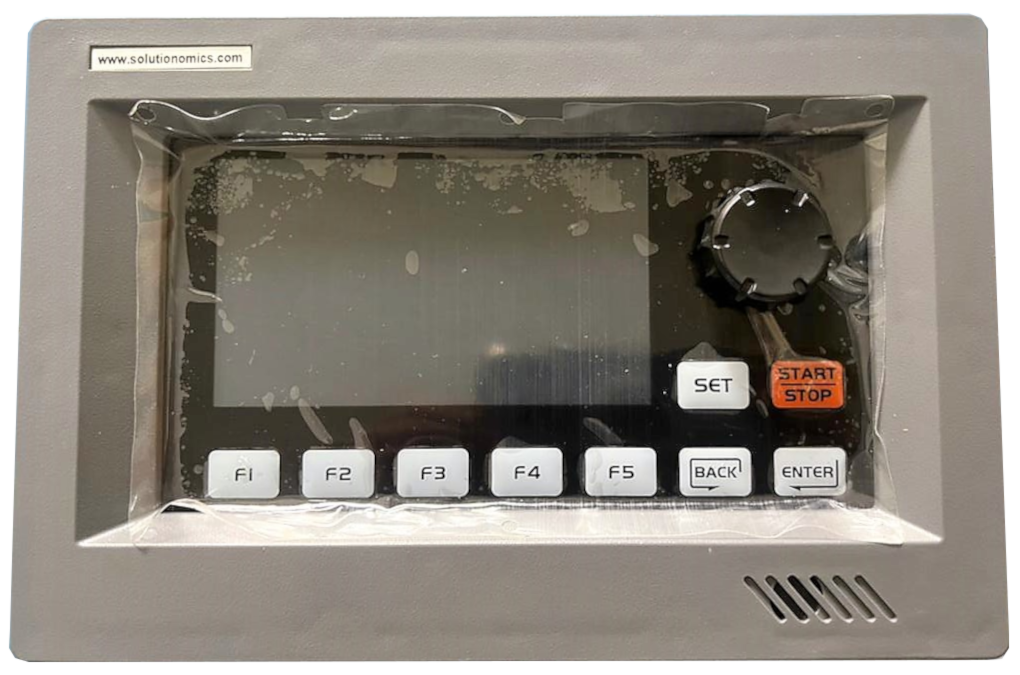

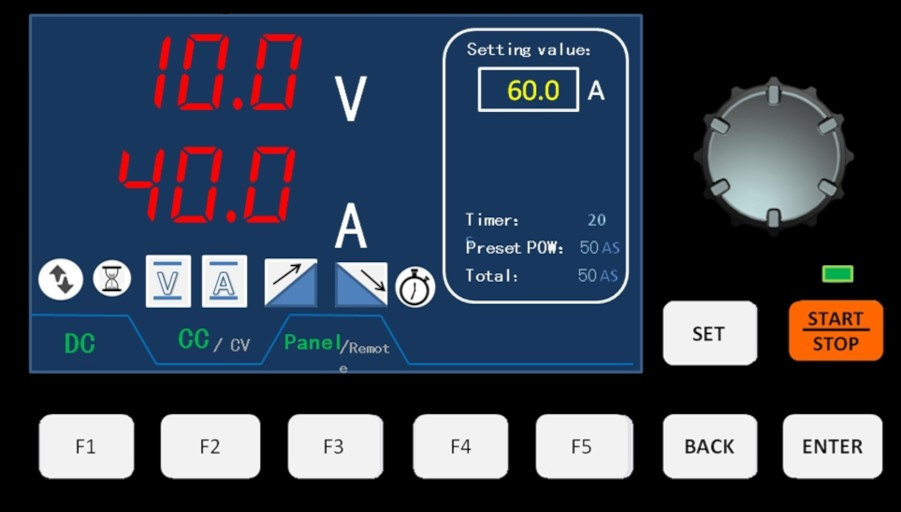

Intuitive LCD Interface

Technology

IGBT programmable high frequency switching power device

DC Smoothed Wave Output

Low ripple smoothed wave electrocoagulation rectifiers suitable for the most stringent wastewater treatment requirements

Standard Features

CONST PR – Constant polarity reversing smoothed wave output

PLC communication port RTU RS485

Optional Features

PLC analogue signal communication port 0-10 V or 0-5 V or 4-20 mA

Parallel pairing

Other Available Rectifier Models

Plating Rectifier

Polarity Reversing Plating Rectifier

Pulse Plating Rectifier *

Polarity Reversing Pulse Plating Rectifier **

* With 3 different wave form.

** With 4 different wave form.

Electrocoagulation

Electrocoagulation Process

Electrocoagulation is an electrolytic process that uses sacrificial electrodes to dislodge and separate from wastewater a large variety of organic and inorganic pollutants without the need to add any chemical coagulating agent.

The sacrificial electrodes are usually made of materials such as iron, steel or aluminum.

Electrooxidation Process

Electrooxidation is an electrolytic process that uses inert electrodes to degrade, dislodge and separate from wastewater a large variety of organic and inorganic pollutants.

The inert electrodes are usually made of materials such as platinized titanium, platinized mixed metal oxides etc.

Electrocoagulation Rectifiers

Compact Bench Top Electrocoagulation Rectifiers

Volt Output Range

Standard unit 0~12 V

Other output on request

Ampere Output Range

Remote Control Bench Top Electrocoagulation Rectifiers

Volt Output Range

Standard unit 0~12 V

Other output on request

Ampere Output Range

50 A, 100 A, 150 A, 200 A, 300 A, 500 A, 1000 A

Remote Control Small Tower Electrocoagulation Rectifiers

Volt Output Range

Standard unit 0~12 V

Other output on request

Ampere Output Range

1500 A, 2000 A, 2500 A

Remote Control Large Tower Electrocoagulation Rectifiers

Volt Output Range

Standard unit 0~12 V

Other output on request

Ampere Output Range

3000 A, 4000 A, 5000 A, 6000 A, 7000 A, 8000 A, 10000 A

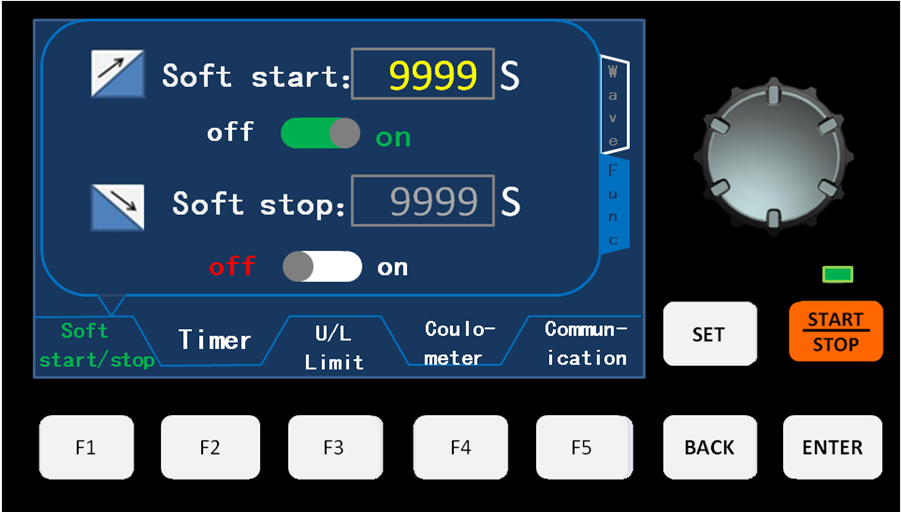

CONST PR– Constant Polarity Reversing Smoothed Wave Output

Mode CV or CC

Output for forward V or A

Output for reverse V or A

Timer for soft start

Timer for soft stop

Timer for forward cycle

Timer for reverse cycle

Timer for total forward and reverse cycles auto cut-off

CV/CC

0 to unit rated output

0 to unit rated output

0 to 9999 S

0 to 9999 S

0 to 9999 S/M/H

0 to 9999 S/M/H

0 to 9999 S/M/H

Simple Operation

Sol Rectifiers PHFSPD EC

These are programmable closed loop self-regulating units, which output can be set from 0 V to unit rated V output or from 0 A to unit rated A output.

Operator pre-sets unit either in Constant Volt (CV) or in Constant Current (CC) mode.

Then pre-sets forward required output for the respective selected mode, for instance 6.8 V when in CV mode or 92.7 A when in CC mode.

Then pre-sets reverse required output for the respective selected mode, for instance 4.2 V when in CV mode or 31.5 A when in CC mode.

Then pre-set the timer to control forward plating duration before the unit automatically reverse polarity.

Then pre-set the timer to control reverse plating duration before the unit automatically reverse polarity.

Then pre-sets the total forward and reverse time during which automatic repetitive polarity reversing cycles will occur, the unit will automatically cuts off the output at the end and rings the alarm.

The moment operator presses the Start key the unit will automatically maintain the pre-set output value no matter any fluctuations in the plating cell resistance or in the main electrical supply to the unit for absolute plating consistency and precise control.

Operator can also pre-set a ramp up time cycle on start. Here the unit will gradually ramp up output to the pre-set output value in the given set time.

Durability & Care Free Operation

Relying on our state of the art electronic protection circuitry, our units are known to operate trouble free for years on and into decades.

When units are placed in a clean fresh air environment, care free operation can be expected. Only minimal air fan cleaning may be required once or twice a year.

Order Quantity & Shipping Options

Single order unit are welcomed.

We ship straight from the factory to any parts of the world.

Depending on order weight or volume the following shipping services are available:

Speed courier

Air freight

Air freight door-to-door

Sea freight

Sea freight door-to-door

Worldwide Customers

We have a large number of satisfied customers using on a daily basis our plating rectifiers in various countries, to name a few:

Australia, Austria, China, Denmark, Indonesia, Malaysia, Philippines, New Zealand, Singapore, South Africa, Thailand, United Kingdom of Great Britain, United State of America, Vietnam, etc.

Specifications

IGBT programmable high frequency switching power device.

Automatic cut-off protection against output over voltage, over current and overheating.

Automatic cut-off protection against AC input over or under voltage and phase distribution imbalance.

Low ripple DC smoothed wave output.

Closed loop self-regulating CV or CC operation.

Precise voltage and current regulation.

Fast response to AC input and DC output variations.

Insensitive to AC input phase sequence.

Large LCD display.

Reliable, durable and simple to operate.

Low electrical consumption.

Small in size and lightweight.

For units with remote controller, the power console can be placed away from the plating tank, hence away from corrosive splashes and fumes and the remote controller close to the plating tank for operator convenience.

The following options are available on request:

1) PLC analog signal communication port: 0 – 5 V or 0 – 10 V or 4 – 20 mA.

2) Parallel pairing for higher current output: up to 4 units of the same output rating can be paired.

Our rectifiers dedicated to water, wastewater and chemical treatment are treated with additional anti-corrosion coating to protect internal component against moisture and corrosive fumes.

220 V Single Phase 50/60 Hz input for units 300 A output and below.

220 / 380 / 400 / 415 / 440 / 480 V 3 Phase 50/60 Hz input for units 500 A output and above.